|

|

|

|

|

| |

Samples & Guides \\ Industry Articles

|

| |

We have gathered some of the better articles related to our niche for your viewing. These articles will give you a better understanding of some of the processes and operations we perform.

|

Article Index

Do's & Don’t'sBy: The Finisher’s Corner

Reprinted from New England Printer & Publisher

Issue: December 1991

DO - ALLOW TRIM.

-

It doesn't matter if you're sending sheets out for die

cutting, mounting, film laminating, stamping or whatever. One of your goals when

laying out a sheet should be to permit the greatest number of options at the

finishing stage. As an example, if you have a 2-up form, don't put the two units

close together leaving oodles of trim left and right. It might be more efficient

to die cut or stamp the job 1-up, and there might not be adequate gripper space

if the units are close together.

DON'T - CUT THOSE SHEETS

-

Especially true when the

registration of die cutting to the printed image must be accurate. The general

rule is to send the sheets to your finisher just as they are delivered from your

press. If the die cutter doesn't have an accurate gripper and side guide for

registration, he can't do his job properly. Since the mounting operation leaves

a rough edge that must be cleaned up with a final guillotine trim, display cards

can't be made full size if the printed sheets are trimmed to final

size.

DO - PRINT SHEETWISE FOR SCORING

-

Scores usually perform best when they are

folded away from the score. If you print a work & turn or work & tumble

sheet that needs scoring, it will have to be run through the scoring press twice

or 1/2 of the job will be scored into the wrong side.

DON'T - PRINT COMMON RADII

-

We're talking here about

die cut round corners, not round corners done on a round cornering machine.

Where two radii butt against each other, the round corner die knives join at a

very acute angle and the result is usually a nick. Leave 14" or more between

units and you'll get cleaner, more continuous round comers.

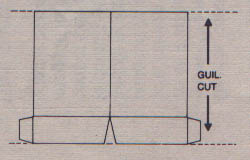

DO - GUIL. CUT STRAIGHT EDGES

-

If all of the perimeter knives in a die are present and

cutting cleanly, the die cut piece and the trim becomes difficult to deliver

from the press in anything resembling a reasonable jog. There are two remedies.

First, the knives can be nicked in several places to leave uncut areas to help

hold the sheet together, or second (and much preferable) straight knives

parallel to either the gripper or the side guide can be left out, and final

trims can be made on the guillotine cutter to free the die cut piece from the

sheet.

DON'T - THINK 3D POCKETS ARE FREE

-

"Hell no, my customer won't pay for 3D pockets, why don't

you just use a wide score to give a little room inside?"

Sure, and the Tooth Fairy will

be along shortly.

The width of a scoring rule is

determined by the thickness and type of stock being scored. Scoring with a rule

that is too wide for the stock being used, will result in crooked, cracking

scores. Not only does folding performance suffer, but you don't gain anything

anyway. The pockets and spine fold flat after gluing regardless of the width of

scoring rule used.

DO - KEEP YOUR BASIS WEIGHT UP

-

Higher basis weights keep your saleshappy. Mounted jobs

look smoother since less of the roughness of the cardboard shows through. Pocket

folders feel better, score better, and have less chance of adhesive bleeding

through the glued areas.

DON'T - PRINT THE DIE LINES

-

If your die cutter is so forgetful that he needs to be

shown where to cut or crease on every sheet, you'd better be thinking about a

change. When the cut or score lines are printed, you've got a disaster unless

the die is perfect and each strike is perfect. Unfortunately this is the real

world. Don't do this to your finisher -- neither of you needs the

hassle.

DO - ALLOW PLENTY OF BLEED

-

Why not? It makes ink salespeople, guillotine cutters, finishers, and customers

happy. Dies are not perfect, die cutting registration isn't perfect, the

printing registration may not be perfect (hard to believe) or there may be some

paper stretch (heavens no!). Anything less than perfection really looks bad

without a bleed.

DON'T - UV COATING AND SCORES

-

Here's the dope on UV coating jobs that fold. If you're

doing a spot UV job, just keep the coating off the scores, and you won't need to

worry about cracking. If your coating is overall, you can best prevent cracking

by keeping the basis weight up and using low solvent, no wax inks. These inks

allow for the best adhesion between coating and ink, and give you the best shot

at eliminating cracking. Please don't coat glue flaps or areas where flaps

glue.

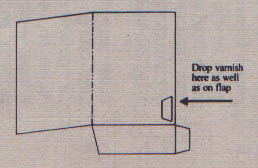

DO - DROP VARNISH FROM GLUE FLAPS

-

I'm sure you always remember to keep ink and varnish off

glue flaps, but don't stop there. The hard to glue stuff must also be dropped

from the area where the flap glues. Bleed color 1/8" into the glue

area.

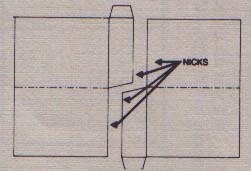

DON'T - INTERLOCK FOLDERS

-

Normally your die cutter will leave out the knife that

creates the bottom of the pocket, and will plan to make this cut on a guillotine

cutter. This helps keep the sheet together as it runs through the die cutting

press and eliminates, or at least minimizes the need for those unsightly

"nicks." When pockets are interlocked, no knives can be left out of the bottom

of the pocket, and the die cut piece must be nicked to keep the sheet together

until it reaches the delivery end of the press.

DO - GET THE SPECS STRAIGHT

-

We're all familiar with the guy who calls before he

understands the job. The conversation usually goes something like

this:

Estimator: "Do you want the job

done this way or that way?"

Customer: (Doesn't have all the

specs) A don't know, please quote it both ways."

Let's not forget that estimators

are often the busiest people on earth they don't need any extra

projects.

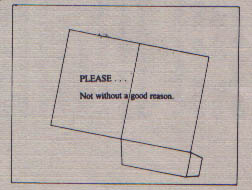

DON'T - PRINT ON AN ANGLE

-

Oh, I suppose it's OK if you're really worried about a

problem solid or a ghosting problem, but please, don't get into the habit. It

can seriously complicate the job of anyone who has to deal with the sheets when

you're done with them.

DO - GET IT OFF YOUR CHEST

-

Do you have some favorite Do's or Don'ts? Maybe you don't agree with some of these?

Send your comments, complaints and additions to us. Get it off your chest

-you'll sleep better.

Article Index

|

| |

1300 East Mermaid Lane, Wyndmoor, PA 19038

[P](267) 682-0844

|

Best

viewed with Microsoft

Internet Explorer @ no less than 800 x 600

Unless otherwise stated, all content contained within

SterlingFinishing.com is the property of Sterling Finishing, Inc.

|

|

|