Article Index

Glued Products

Reprinted from New England Printer & Publisher

Issue: June 1992

We hope the few minutes it'll take to read these production tips will insure a trouble

free experience with your next die cut and glued project. The focus is on pocket folders,

but most of the tips apply equally to all glued cover stock products.

First, let's consider the stock weight. Beware of any stocks thinner than 8 points.

These thin stocks are too light to provide either a good, durable finished product or a

crisp score. Glues tend to "pucker" thin stocks, particularly if coated 2 sides.

We recommend using a sheet between .008" and .014" for the best combination of

runability, durability and feel.

Second, consider using a standard die. We have lots of standard dies, and for short

run jobs your savings can be significant if we can use one of them. For example, dies for

the basic 1 and 2 pocket folders with and without glue flaps are available in 3 page sizes

and 2 pocket sizes with and without slits for a business card. While we aren't at liberty

to let you use a die owned by one of our customers, we're happy to let you use any folder

die that we own. Give us a call.

Third, consider a custom die. If a standard die just won't do the job, we can

produce a die for any configuration. We make our steel rule dies in-house, so the

turnaround is quick, and the quality is tops. A die made specifically for you is your

property, and will not be used for anyone else. You can leave the die with us for safe

storage or you can have it returned to you with the job. The choice is yours.

Fourth, consider where to put the image on the sheet. We need trim, so try to allow

at least 3/4" on all 4 sides. With 2-up forms, whether work and turn, tumble or

sheetwise, please center each image in its own half of the sheet. With work and tumble or

work and turn sheets, we always have to cut to 1 -on so that the scores will be into the

correct side of the sheet, and centering each image in its own half of the sheet will help

insure gripper bite and trim.

Fifth, please don't trim the sheets. We want all the trim we can get. If you've run

the job 2-up, send us the sheets as they are delivered from your press. If the run is long

and the form is sheetwise it might be more efficient for us to run the job 2-up, and we

would like to preserve that option.

Sixth, to drop out or not to drop out. Please, keep varnish off the glue flaps and

the areas where the flaps glue -- but everyone knows that. We're often asked if a printer

should drop out ink as well from the glue areas. In general our feeling is "why

not?" Our glues stick very nicely to most inks, but some inks contain gobs of varnish

and can cause a problem. So why take the chance?

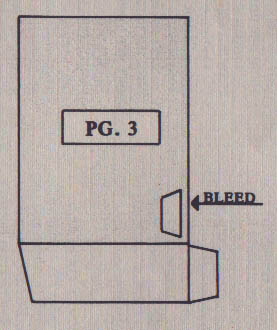

| Seventh, bleed. Of course you always remember to add bleed wherever coverage

reaches the edge of the piece, but don't forget to bleed into the "no glue"

areas. Also, it you're working with glue flaps on the pocket, be sure to add bleed to the

outside edge of the page 2 or 3 glue dropout (area to which flap adheres). When printers

forget this area, the result is that a white strip shows beside the glue flap score.

|  |

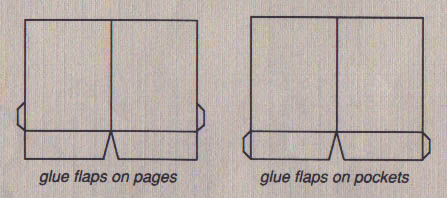

Eighth, give some thought to where your glue flaps should be. As you can see from

these illustrations, there are two places to put the glue flaps on a standard pocket

folder. Which is best?

Both can be die cut and glued equally well. Some designers prefer the glue flaps on the

pockets to give a cleaner page edge, but in most cases you'll be safer with the glue flaps

coming off the side of the page and adhering to the inside of the pocket. This

configuration allows slightly easier insertion of literature, and it prevents the adhesive

from bleeding through or puckering the front and back pages at the glue areas. Some stocks

(coated 2 sides) and some inks (metallic, reflex, and dark colors with varnish) are

particularly prone to puckering, and whatever configuration keeps glue from these

sensitive areas is best.

|

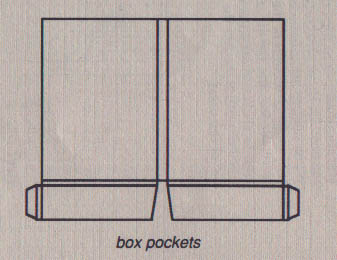

Ninth, Let's talk about box pockets. There are two things you and your customer

should know about box pocket folders. They are time consuming to produce, and they are

very expensive. Designers who specify them often don't know that box pockets cannot be

glued automatically, or that the finishing costs will be at least triple the cost of

producing flat pocket folders. Sometimes the customer may have no idea how much extra they

are paying by asking for 1/8" box scores, so let's be sure to tell them. It might be

helpful to remind your customer how much material they can routinely put into an envelope

with single scores. |

Tenth, please send us a rule up. There are countless variations on the pocket

folder theme, so don't assume that what you are looking for is

"standard". Show us your page and pocket sizes, show any bindery trims, and be

sure to show both style and location of any business card slits. Specifications change

constantly, so even if you told us something during the estimating phase, tell us again

when it comes time for production. We can't assume every job will run as discussed at

the estimating stage, because most of them don't.

Article Index