|

|

|

|

|

| |

Samples & Guides \\ Industry Articles

|

| |

We have gathered some of the better articles related to our niche for your viewing. These articles will give you a better understanding of some of the processes and operations we perform.

|

Article Index

Mechanical Binding: Talk the TalkBy: Anna Massey

Reprinted from Binding, Finishing & Distribution

Issue: January/February 1999

Very often during the course of a day, we hear (or speak) words or phrases that are being used incorrectly. And in production and purchasing, these words or phrases

are not interchangeable.

The problem: one misspoken sentence may mean cutting in half (or doubling) the actual thickness of a book. Or an incorrect reference may mean the wrong binding is used on a job.

Staff and customer training can mean the difference between doing it right and re-doing it right. Errors can be reduced in the Bindery by taking the time to explain the terminology to your employees and your customers. Teach them how to "talk the talk".

Terminology

Saying Pages vs. Sheets is probably one of the most common errors.

It is always best to give specifications by stating the number of sheets in the finished book, not the number of pages.

For example, a book printed on both sides may be numbered to 144 pages but only use 72 sheets of paper…and 72 sheets measures a lot thinner then 144!

As well, whether or not all the pages are printed does not matter in the Bindery.

It is the number of sheets of paper, the book thickness, that is critical!

Mechanical binding "uses a comb, coil, ring binder, post or any other technique not requiring gluing, sewing, or stitching" (definitions from

Graphically Speaking by Mark Beach).

For example, the plastic or wire is inserted into die-punched holes along the spine of the book in order to bind it. The pages are not attached to each other, only gathered and bound by the plastic or wire.

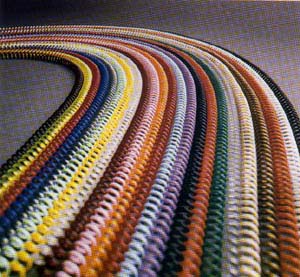

Spiral Binding (also called Coil Binding) seems to be used on the job to describe just about everything. In reality, Spiral Binding is binding done "by using a spiral of continuous wire or plastic looped through holes."

Specifically, Plastic Spiral Binding is a continuous, single strand plastic spiral binding.

Single Strand Wire Spiral is similar to plastic spiral except it is metal.

|

|

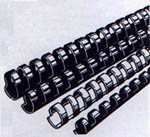

Plastic Comb Binding is a plastic binding with teeth (or flaps) that are opened. Rectangular hole punched sheets are placed on the teeth and the comb is closed.

|  |

|

Double Loop Wire is a coated wire that appears to have two loops running through each punched hole.

|

Pitch

For all four of the above, pitch describes the spacing of the punch holes and/or the spacing between each loop of binding. This term is, without a doubt, the one that

confuses most people!

Specifically, plastic spiral binding is manufactured in various pitch patterns. It is very important when ordering to specify the pitch. If the wrong pitch of coil is ordered, it will not run through your punch holes, not match your pattern.

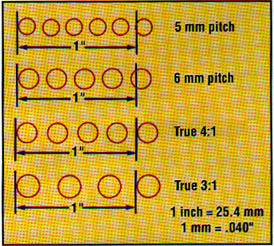

5mm Pitch - This means there are 5 millimeters between the center of a hole (or loop of coil) to the center of the next hole. A metric 5mm pitch is roughly equivalent to 5 holes within every inch. (See diagram.)

6mm pitch - This means there are 6 millimeters between the center of each hole and the next. These holes are slightly farther apart than the 5mm pitch, resulting in a little wider spaced hole pattern. Some people assume that 6mm pitch means 6 holes per inch, which is wrong!

A 6mm pitch hole pattern will result in four and a partial 5th hole per inch.

True 4:1 pitch does not use the metric system. It means that there are exactly four holes within every inch.

|  |

If you convert "True 4:1 to a metric pitch it would be equal to a 6.35 mm pitch.

Another important note: True 4:1 and 6mm pitch, although close, are not the same. They cannot be easily interchanged. Note that these pitch examples are the most common.

However some manufacturers offer pitch patterns exclusive to their product.

These are just a few words - but their meaning makes a huge difference in the Bindery and Purchasing departments.

Article Index

|

| |

1300 East Mermaid Lane, Wyndmoor, PA 19038

[P](267) 682-0844

|

Best

viewed with Microsoft

Internet Explorer @ no less than 800 x 600

Unless otherwise stated, all content contained within

SterlingFinishing.com is the property of Sterling Finishing, Inc.

|

|

|